TORQUE SCREWDRIVER

Precise – Ergonomic

Ergonomic screwdriver tailored to all watchmakers' needs

This torque screwdriver was specially designed to meet production needs.

It stands out for its intricate ergonomics, robustness and high-precision screwing system.

The stainless steel body, 10 mm in diameter, has a fluted profile for a comfortable grip. Unlike knurled surfaces, it does not trap impurities and is very easy to clean, making it a tool perfectly suited to tough environments.

The symmetric head, clipped onto two ball bearings, was designed to adapt to any morphology. Its universal shape can be replaced with other models, available in different sizes and lengths. This enables every user to configure the tool according to the shape of their hand, thereby considerably reducing the risk of musculoskeletal disorders.

Its major innovation lies in its new blade fastening system. No more side screws coming undone upon impacts: the quick-fit ACR blades can be instantly replaced without the need for any tools.

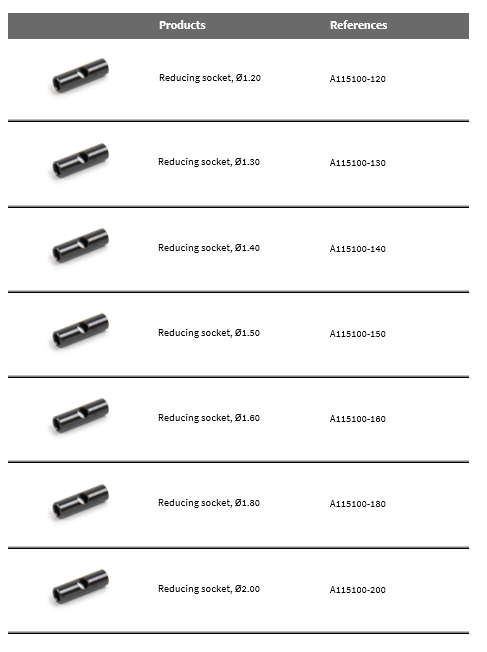

There are also reducing sockets available to ensure compatibility with any blade diameters.

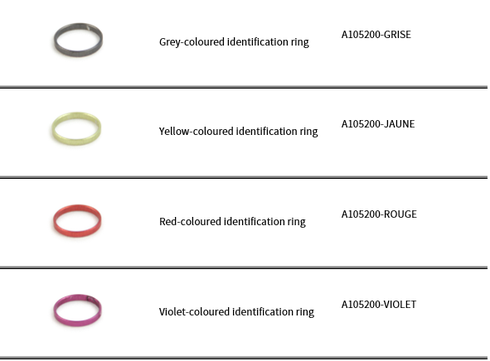

For rapid identification, you can customise your screwdriver using coloured rings. These make it easy to mark the tightening torque or blade diameter used.

At the heart of the tool is a patented mechanism, ensuring remarkably precise screwing. The screwdriver has an intuitive internal torque setting, ensuring perfect control every time you use it.

Finally, to meet specific needs, we can manufacture custom blades, in small or large runs. Whether by sharpening, machining, grinding or spark machining, we tailor our solutions to your constraints to boost your performance and limit screw marking.

Technical specifications:

· Repeatability ±5%

· Type A: two-way, 5 to 60 mN.m

· Type C: one-way, unscrewing locked, 5 to 60 mN.m

REcommendations:

The torque can be set quickly and precisely thanks to an accessible, well-designed internal system.

All you have to do is remove the rear cap using the key supplied with the screwdriver. Once you have done this, the counter-nut inside the tube can be undone slightly.

This will provide access the setting screw. Screw it in to increase the torque. Unscrew it to reduce the torque. For an optimal setting, it is recommended to use an analogue torque meter, such as the TOHNICHI ATG model, if you know the target torque.

Once the setting has been made, it is essential to correctly retighten the locknut, to ensure a reliable hold over time. Firm tightening ensures that the setting will not be disrupted in use, even under intense conditions.

IDENTIFICATION

To enable easy identification of the torque of your screwdrivers, it is possible to add coloured rings between the screwdriver's cap and tube.

AccessorIes :